Situation

As part of a large-scale mining project, the client required a domestic wastewater treatment plant (WWTP). However, the WWTP procurement was initially overlooked in the project planning and posed a risk of delaying the mine startup. The client sought a solution that would be delivered quickly while maintaining capital discipline.

Solution

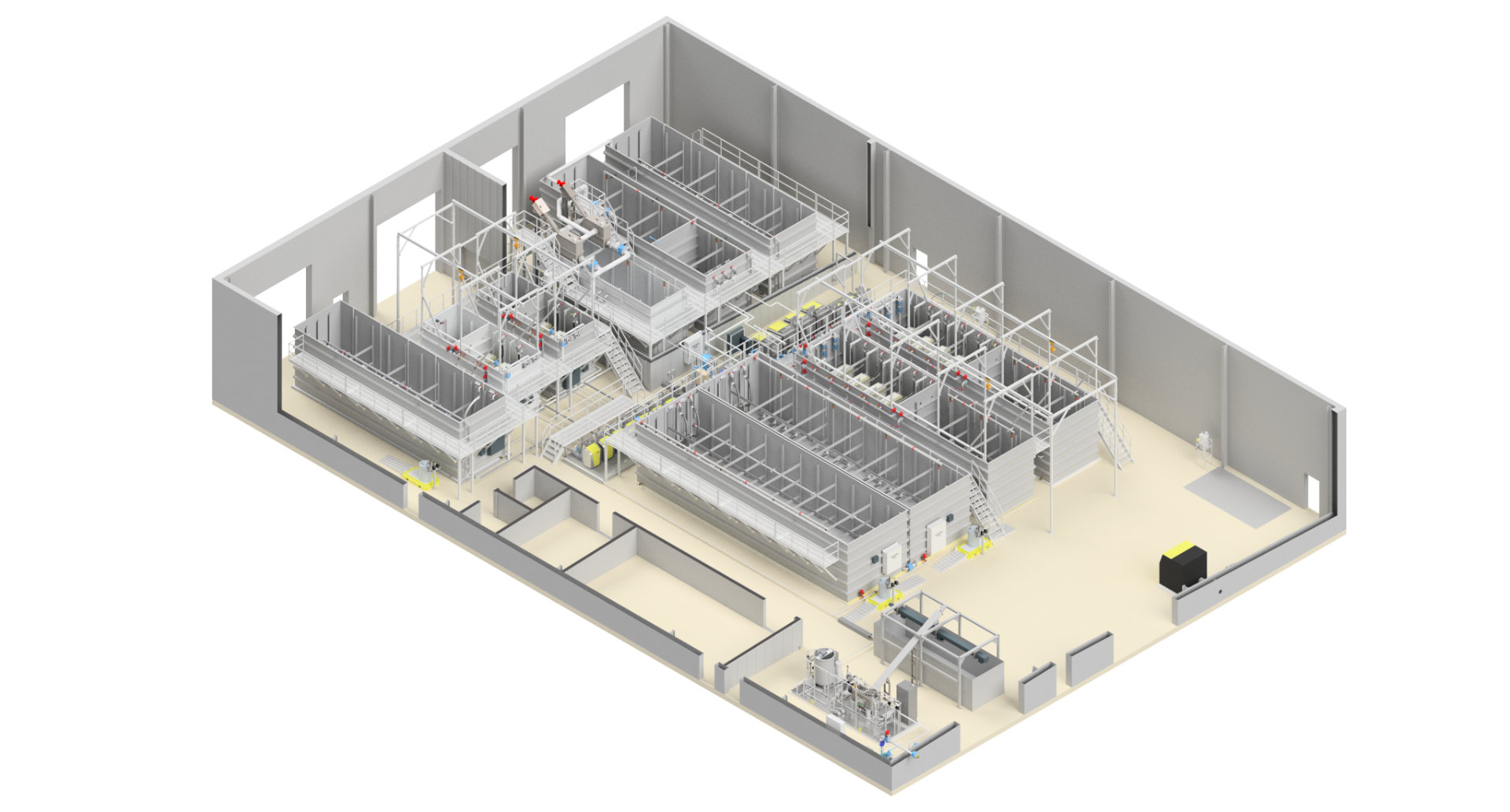

AWC proposed a modular design for a turnkey WWTP. All skids and tanks were pre-wired, pre-piped, and pre-tested, minimizing on-site work to process connections and interconnecting piping. This approach significantly reduced the project timeline compared to traditional installations involving concrete tankage.

Outcome

The modular design of the WWTP allowed for all civil and building works to be completed concurrently with the mechanical and fabrication work for the factory built WWTP. In addition, the civil works were streamlined compared to a traditional plant, requiring only a concrete slab for equipment placement, which reduced engineering and construction time. As a result, the construction of the plant, which could have posed a risk to the startup of a multi-billion-dollar project, was de-risked and completed ahead of schedule.

Client: a global mining company

Treatment Capacity: 780 m3/day

Technologies Employed: Primary screening, flow equalization, aeration, membrane bioreactors, sludge holding, centrifuge dewatering, solids conveying, chemical systems.