Situation

A wastewater treatment plant located along the Hudson River had reached the end of its effective lifespan, experiencing failures of underdrains and basin troughs, resulting in a series of operational issues. As a result, the plant was unable to consistently meet its discharge requirements for flow and water quality. The client needed a solution to restore the equipment and operational reliability of the plant, and to ensure compliance with flow and permitted effluent quality requirements.

Solution

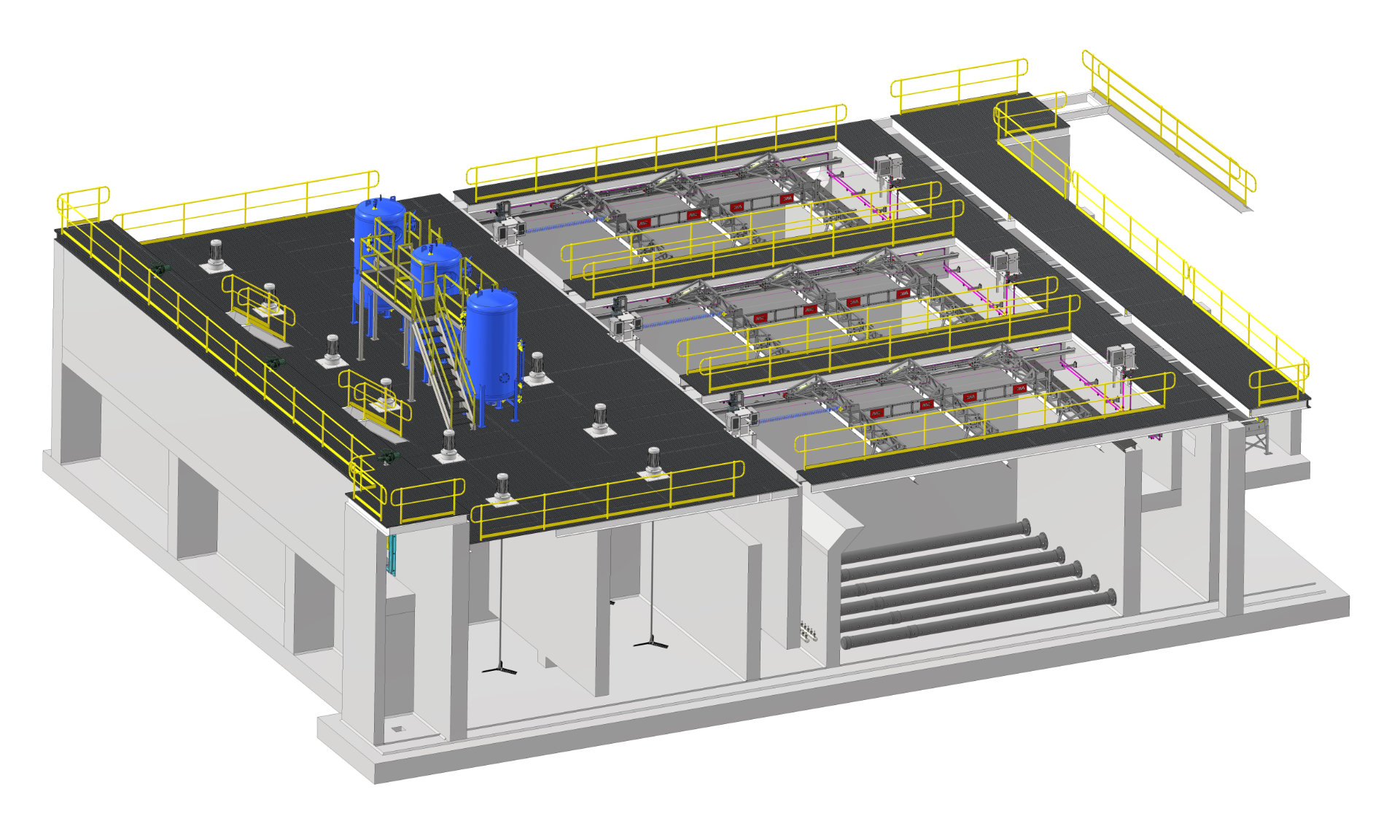

AWC was the sole vendor to commit to completely replacing the entire dissolved air flotation (DAF) and filtration systems within ten existing concrete DAF/filter basins. To minimize interruptions, each filter was taken offline one by one to reduce interruption of the system. All components were custom designed and prefabricated for rapid installation at the site.

Outcome

As a result of AWC’s solution, the capacity and reliability of the plant were fully restored to 100%, and the plant achieved the highest discharge water quality ever recorded.

Client: a municipal sewerage authority in New Jersey, United States

Treatment Capacity: 151 MLD (40 MGD)

Technologies Employed: Dissolved air flotation, gravity filtration.