Situation

A mining client had fallen behind schedule on their equipment procurement for a remote arctic mine and urgently needed a pressure filtration package in an all-weather enclosure for mine-affected water. With only 12 weeks before the last barge of the season departed, they sought a partner who could deliver a custom treatment package in less than half the normal lead time.

Solution

Upon receiving the client’s request, AWC immediately took action. All major equipment was ordered within 24 hours of the notice to proceed. AWC maintained constant communication with the client, seeking approvals and overcoming barriers almost hourly. A second shift was added, and both shifts worked 12-hour days to ensure continuous progress. Leveraging AWC’s extensive design library, AWC adapted elements from previous designs to meet the unique requirements of this client.

Outcome

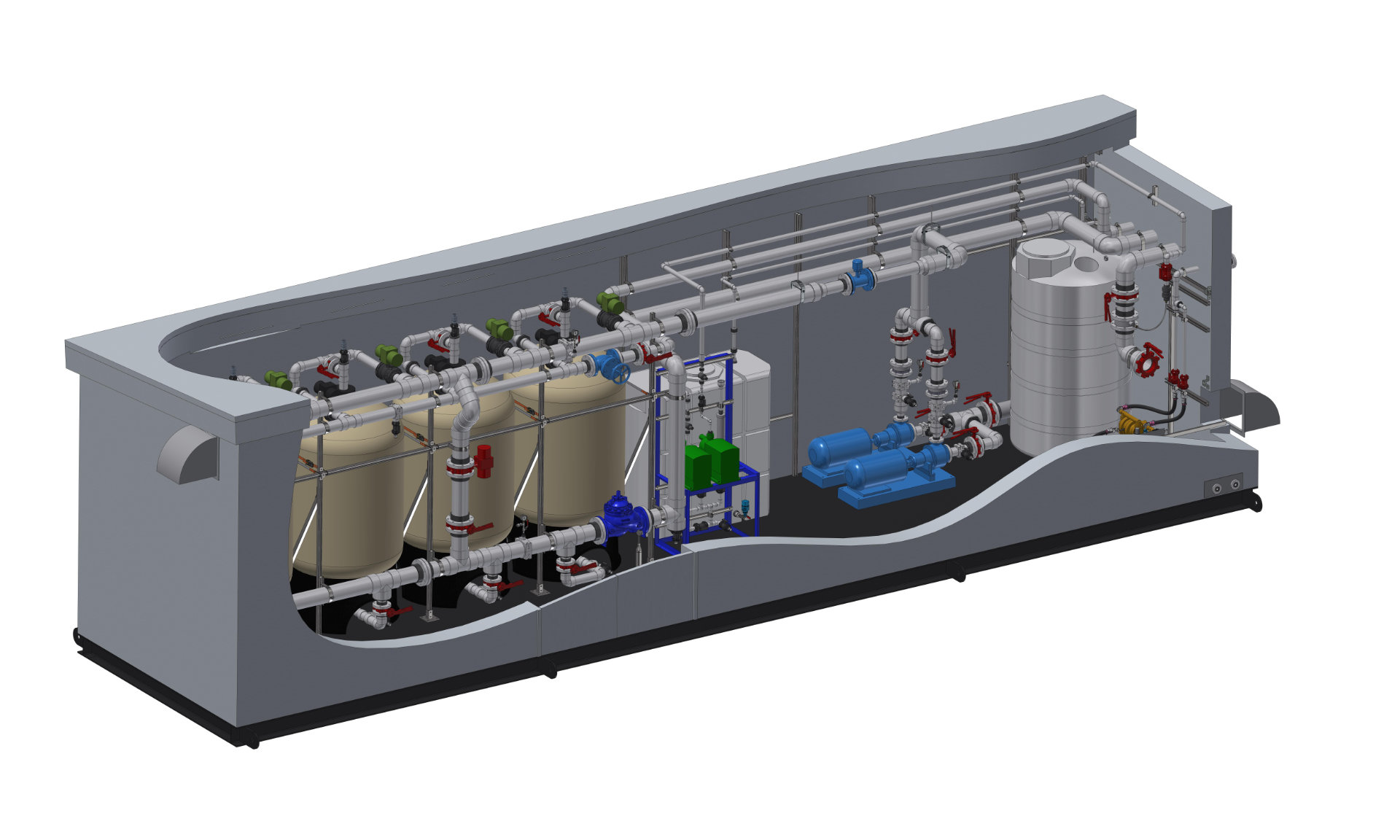

Due to effective communication, expediting efforts, and round-the-clock production, the custom treatment package was delivered on time to the barge shipping location. The plant is now operating year-round in its heated enclosure, helping the client meet required discharge limits and ensuring smooth operations at their remote arctic mine.

Client: a remote mining facility in the Canadian arctic

Treatment Capacity: 240 gpm (54.5 m3/hour)

Technologies Employed: Pressure filtration, chemical systems, backwash system.