Situation

AWC was the successful proponent for the pre-selection of the major treatment equipment for a municipal drinking water project for a coastal community in the Pacific Northwest. The balance of plant was designed based around AWC’s treatment module and was to be site-constructed by a general contractor. However, all general contractor bids for the balance of plant construction came in significantly over budget after going out to tender. The community did not have additional funds, and the project faced potential shelving for several years. Meanwhile, the existing treatment plant was out of compliance with local Health Authority requirements.

Solution

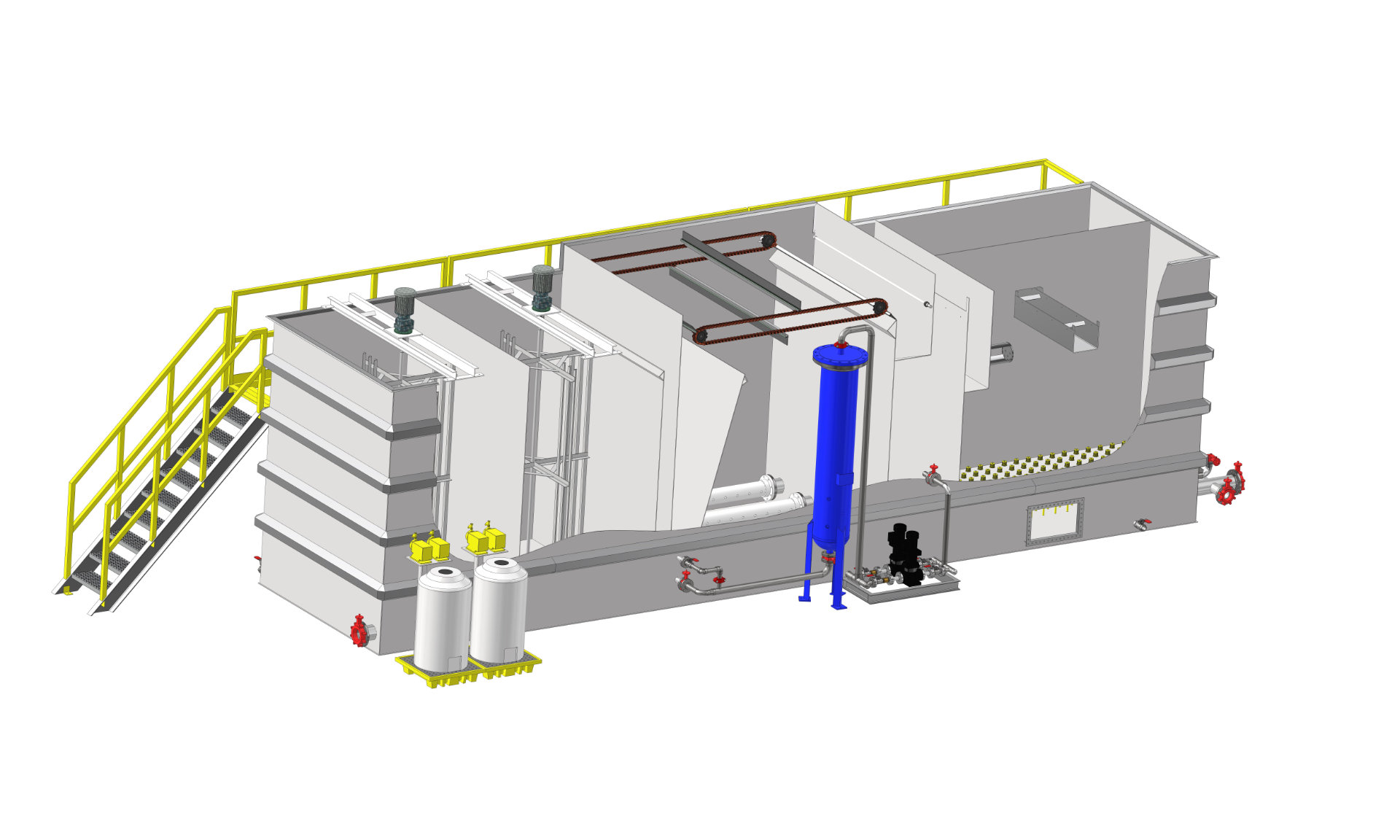

AWC worked with the community and their engineer to provide value-engineering alternatives to make the project financially viable. This included various design changes, such as adopting a modular factory-constructed building, modifying tankage requirements, altering the raw water and distribution pumping system, and implementing an alternative reservoir design. AWC also provided a process guarantee for the design and helped assemble a design-build team to streamline project execution and reduce costs.

Outcome

Despite a delayed start due to the complete redesign, the plant was successfully built and commissioned within the original budget. In fact, the project was completed under the initial budget, representing a savings to the community compared to the lowest bid for the original design. Most importantly, the community was able to secure a reliable source of fresh and clean water that met all drinking water standards, ensuring compliance with local Health Authority requirements.

Client: a coastal community in the Pacific Northwest

Treatment Capacity: 320 gpm (72.7 m3/hour)

Technologies Employed: Dissolved air flotation, chemical dosing, disinfection, water reservoir, modular building, design-build.