Situation

A mining client was in the process of constructing a mining operation on Baffin Island, requiring potable water treatment at two locations: the inland mining operation and a processing facility on the shore. Compliance with permit waste discharge requirements and cost-saving measures for waste handling infrastructure were crucial. Furthermore, the equipment needed to be compact, factory tested, pre-assembled, and pre-wired for convenient installation and transportation by rail and barge. Meeting the shipping deadline was critical due to the seasonal ice pack, with no option for delays.

Solution

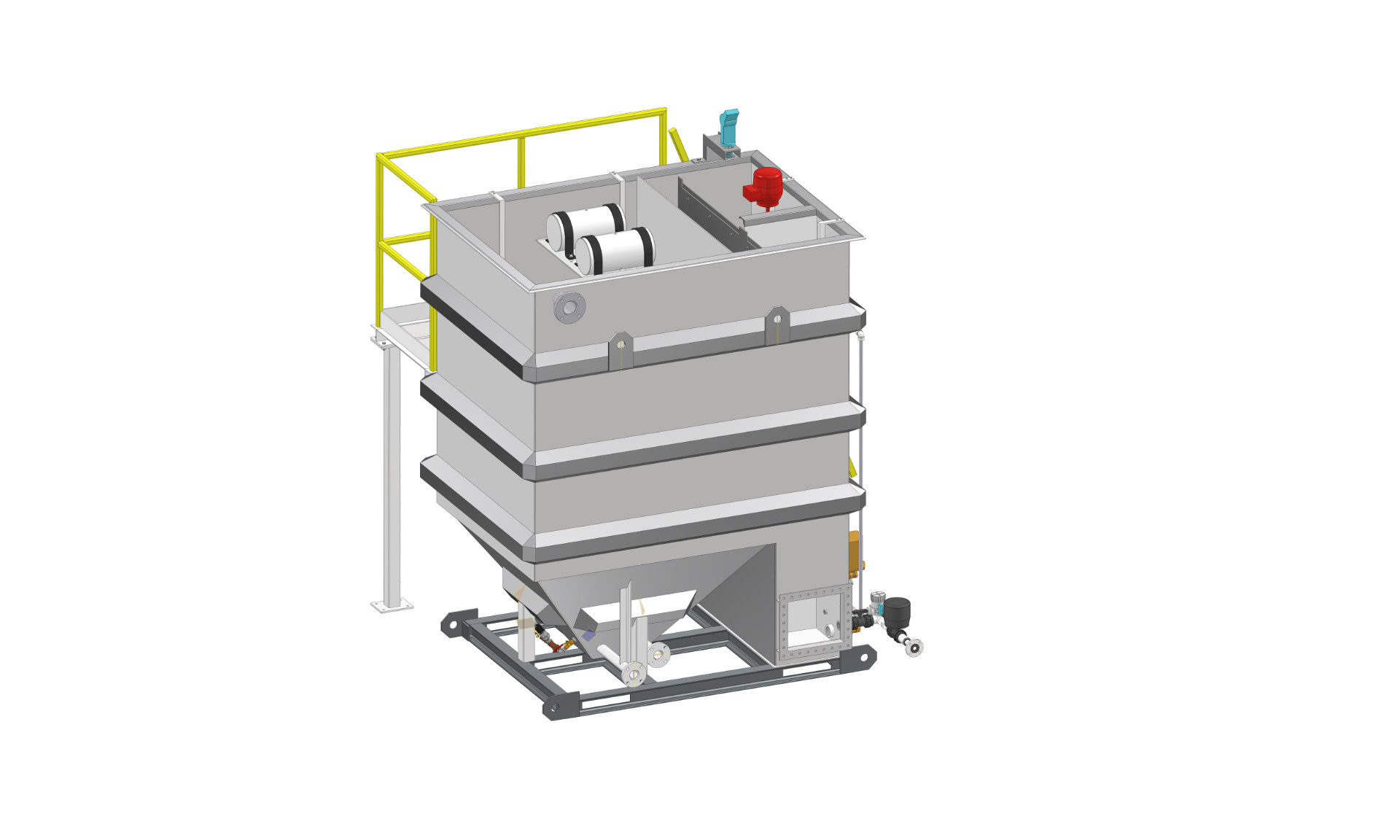

AWC devised a custom-designed solution that incorporated a compact treatment system with residuals recovery in a single unit for each location (total of 2 units). This unique approach allowed for compliance with permit waste discharge requirements and minimized waste generation. AWC overcame the handling constraints and manufactured a specialized product to meet the shipping deadline.

Outcome

AWC successfully met all the requirements, with the equipment achieving close to 99% recovery, and less than 1% of the plant’s throughput went to waste. This efficient and sustainable solution allowed the mining company to comply with permit requirements, save on waste handling infrastructure costs, and meet the strict shipping deadline, ensuring a successful outcome for the project.

Client: a Canadian mining company

Treatment Capacity: each plant, 15 gpm (3.4 m3/hour)

Technologies Employed: Adsorption clarification, backwash thickening.