Situation

The client required a 4 MGD tube settler clarifier for their project. They preferred a packaged plant as the project delivery method to reduce capital costs and improve delivery time. However, due to the large flow range and the need to account for cold water temperatures affecting reaction time and water density, finding a supplier and designing a packaged plant posed challenges.

Solution

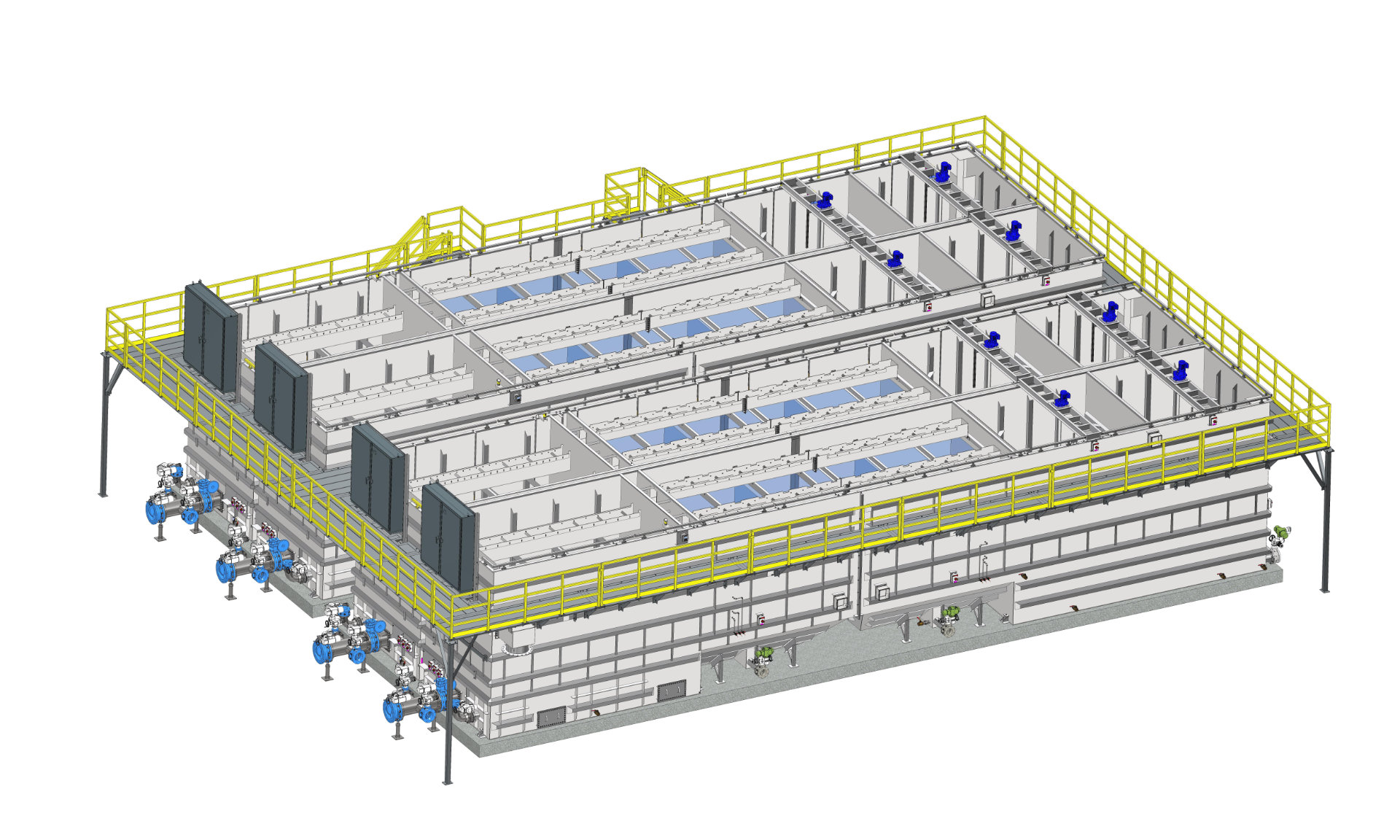

AWC collaborated closely with the client to custom design four flocculation/clarification/filtration trains, each with a capacity of 1 MGD. These trains were fabricated in two large modules, measuring approximately 10′ wide by 14′ high by 65’ long, which were flanged and welded together on site under the supervision of an AWC factory representative. All plants were fully fabricated, assembled, and tested at AWC’s factory, saving installation time and time to start-up and commission.

Outcome

The packaged water treatment plants were delivered months ahead of the project schedule and saved substantial capital costs compared to site-constructed options. The plants arrived at site fully wired, piped and extensively tested (prior to leaving AWC’s production facility), which allowed for the installation and commissioning to be completed in a few days and with zero deficiencies.

Client: a ski village in the United States Rocky Mountains

Treatment Capacity: 4 MGD (634 m3/hr)

Technologies Employed: Flocculation, clarification, media filtration, chemical systems, backwash system.