Situation

Local governments in Canada’s northern territories are tasked with supplying clean and safe drinking water to numerous remote communities, some of which lack road access. However, with rising federal water standards and deteriorating infrastructure, several potable water treatment plants required replacement. Due to the challenging logistics and harsh arctic environment, traditional design-bid-build approaches were not economically viable for executing these projects.

Solution

The local government chose to utilize a tender for design-build project delivery instead of the traditional design-bid-build model. Under the design-build model, multiple proponent teams are invited to propose their innovative ideas and approaches to deliver critical infrastructure with the best value for money. This differs from the traditional design-bid-build model, where proponents bid on a pre-defined design provided by an Owner’s Engineer without the flexibility to propose unique solutions or approaches.

Outcome

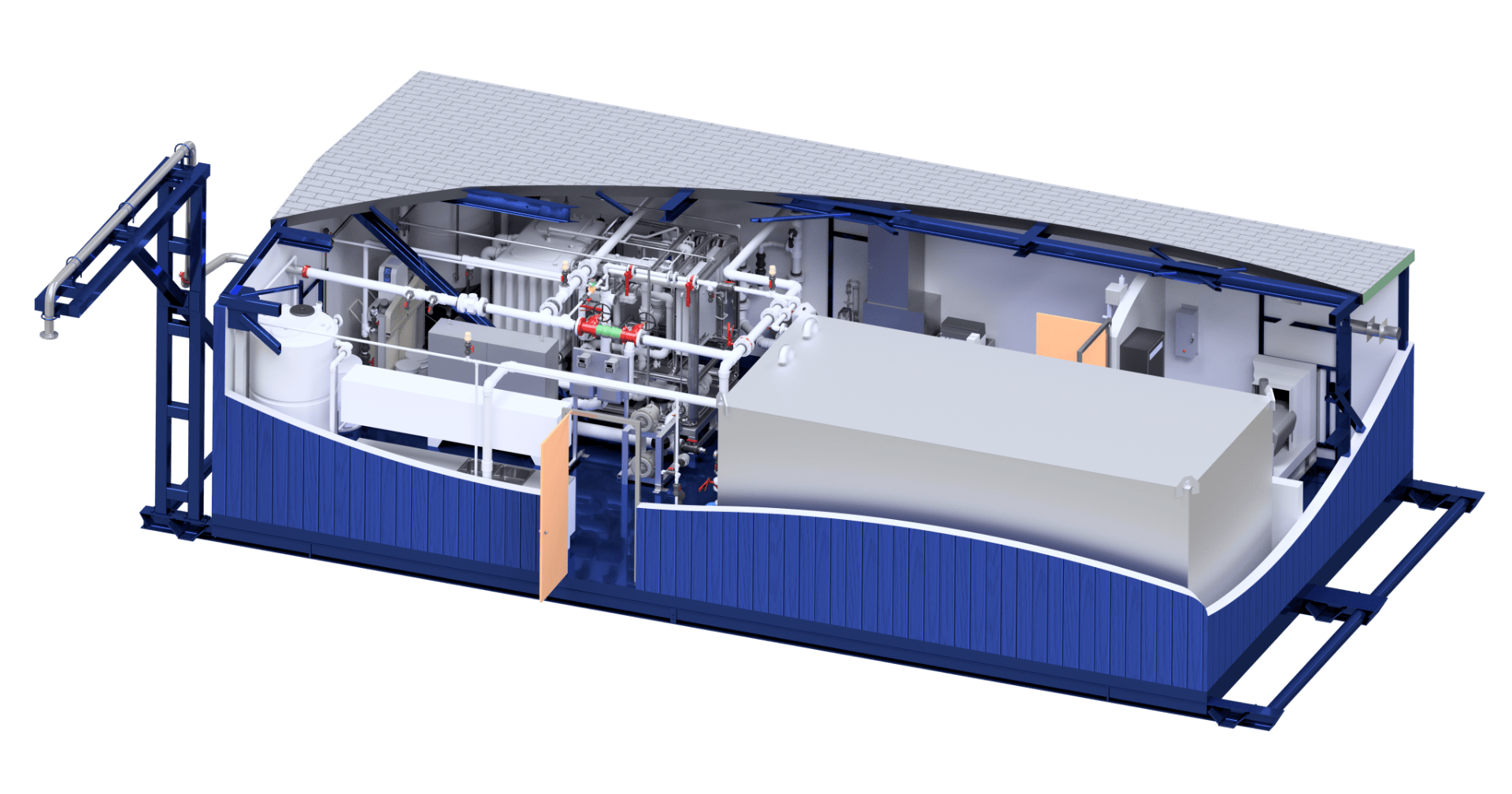

As the successful proponent, AWC formed a team of local engineering and construction partners who had valuable insights into the needs and dynamics of the communities. AWC successfully delivered three drinking water plants ahead of schedule and under budget. The selected process was submerged membrane ultra-filtration (UF), chosen for its compactness and ability to handle varying raw water conditions. The bundled design-build approach resulted in a cost reduction of approximately 75% compared to estimated costs of a design-bid-build strategy. AWC’s expertise in executing projects in remote and arctic environments was crucial for the smooth project execution. To date, AWC has delivered multiple plants, including those beyond the arctic circle, for this client under this model.

Client: a territory in Northern Canada

Treatment Capacity: Three (3) different plants, each operating at 30 gpm.

Technologies Employed: Ultrafiltration (submerged), post-disaster modular buildings, truck fill system, chemical systems, water storage tank.